Description

Different Gap-Type Filter Designs

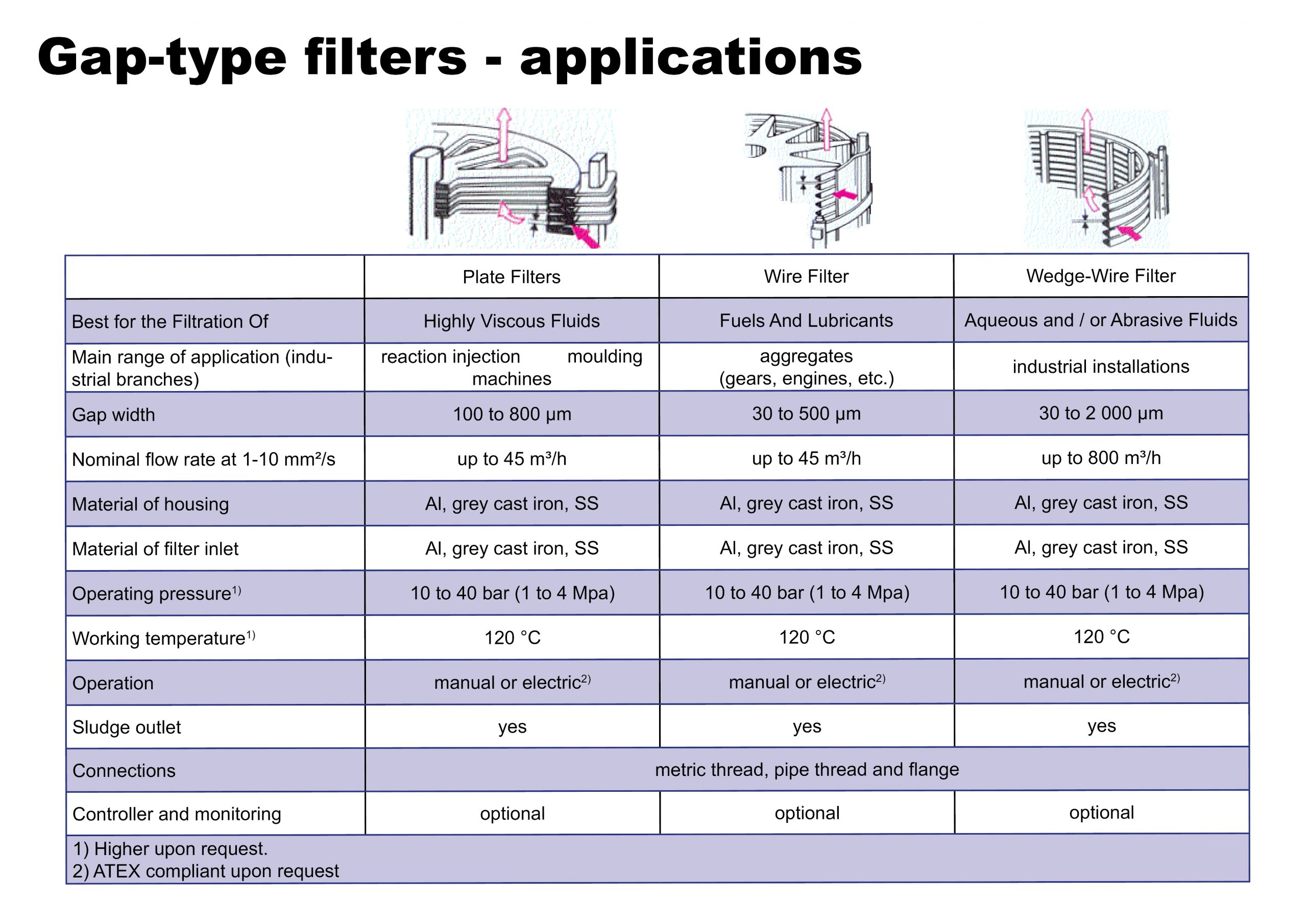

Plate Gap-Type

Plate gap-type filters for gap widths ≥ 0.1 mm

The plate gap-type filter insert consists of ring-shaped steel discs piled up on a central pin. The gap width between the discs is determined by spacers between the discs. A stationary gap cleaner runs through each gap. As the liquid flows between the discs, dirt particles in the liquid are deposited on the surfaces of the gap. When the handle of the filter insert is turned the dirt particles gather on the row of gap cleaners and sink to the sludge collection chamber where the sludge is discharged by opening a ball valve.

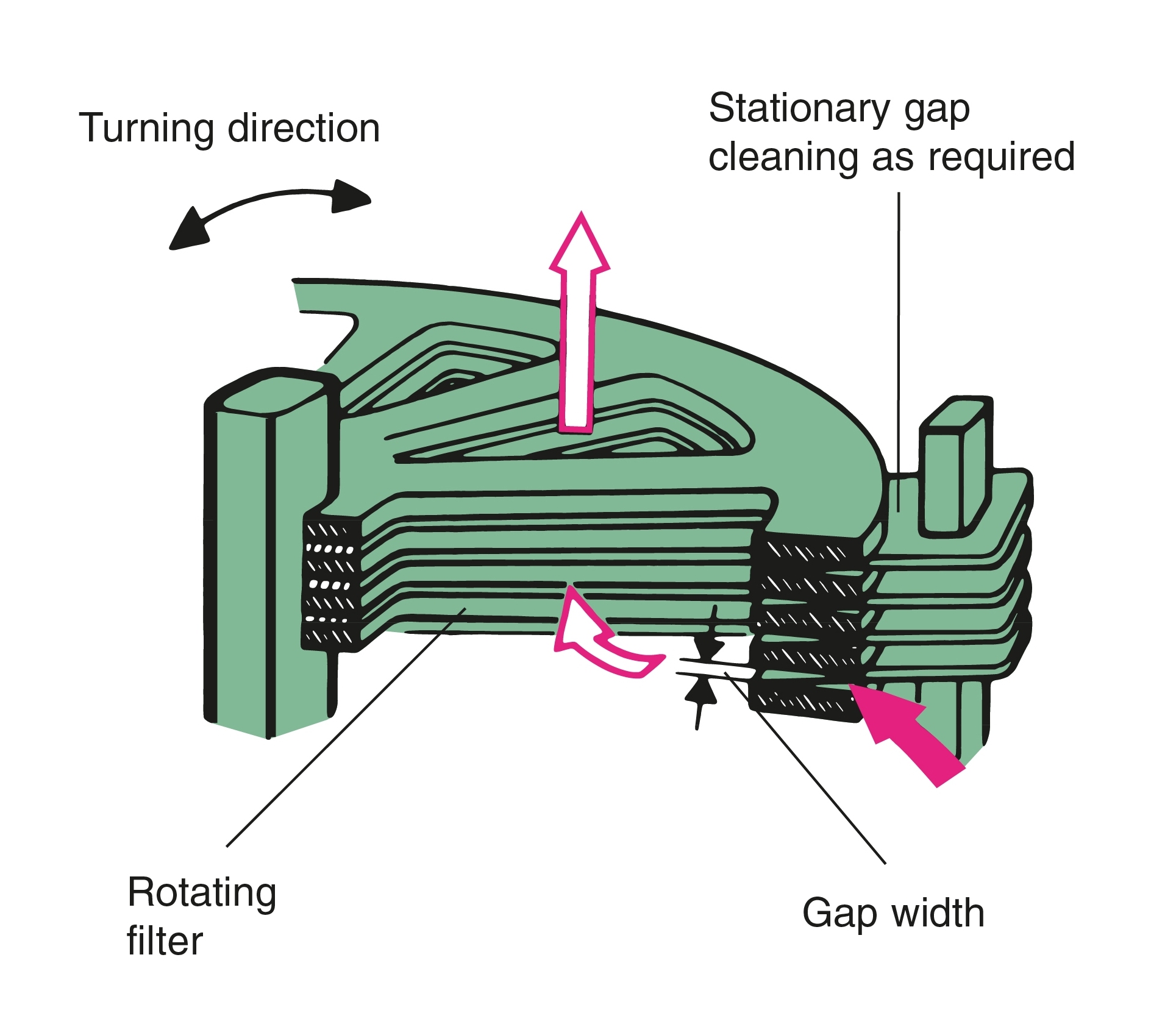

Tube Gap-Type

Gap-type tube filters for gap widths ≥ 0.03 mm

Gap-type tube filters for gap widths ≥ 0.03 mm

The gap-type tube filter insert consists of a wire wound around longitudinal rods welded together at every crossing point. The longitudinal rods and wire are made of nonrusting, high tensile steel. The exact position of the steel wire on the longitudinal rods provides for equal gaps. As the liquid to be filtered flows through the filter insert the dirt particles are deposited in the gaps. When the handle on the filter insert is turned, the dirt particles are removed by a stationary scraper and fall down into the sludge collection chamber. The sludge is discharged by opening a ball valve.

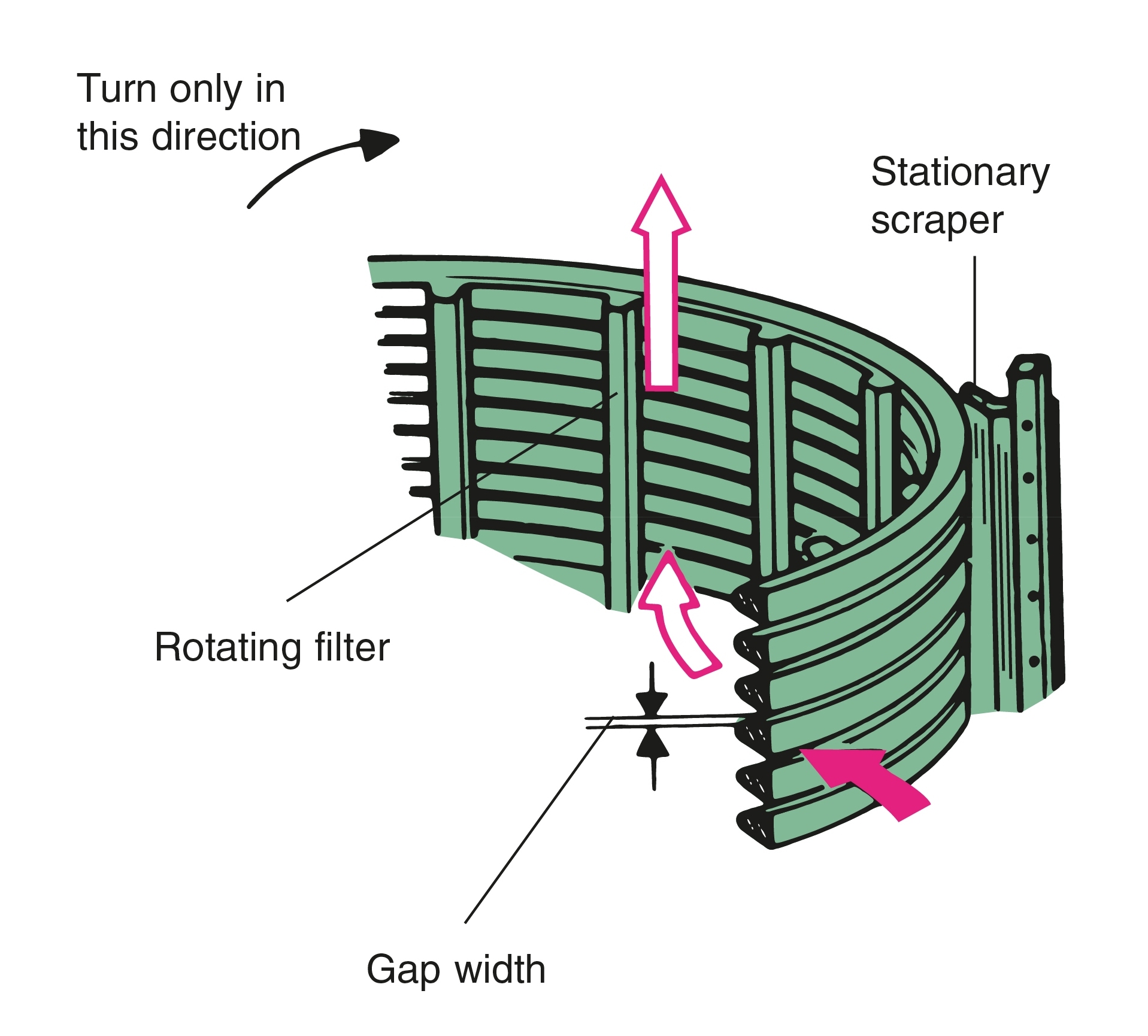

Wire Gap-Type

Wire gap-type filters for gap widths ≥ 0.03 mm

Wire gap-type filters for gap widths ≥ 0.03 mm

The wire gap-type insert consists of a non-rusting, high tensile steel wire wound in a spiral around an aluminum frame. The exact position of the steel wire on the frame provides for equal gaps. As the liquid to be filtered flows through the insert dirt particles are deposited in the gaps. When the handle of the filter insert is turned the dirt particles are scraped by a stationary cleaner and sink to the sludge collection chamber where the sludge is discharged by opening a ball valve.