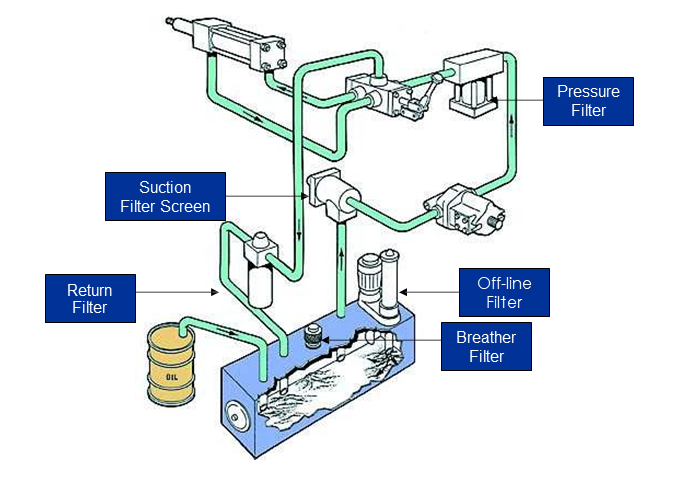

It is very important to select a filter that will improve the reliability of the lube or hydraulic system to eliminate failure due to contamination. Let us look at the various options for the location of a filter. There are no known mathematical models that will easily locate a filter in a given system. Even today, the location of the filter remains subjective and it is up to the system designer to locate a filter to suit the system. However, there are a few locations that are predominantly used in lube or a hydraulic system.

This filter is located on a suction port of the pump or submerged in the reservoir and attached to the suction line leading to the pump. A suction filter intends to protect the pump from large particles found in the reservoir. This filter is usually a coarse mesh filter or even a magnetic separator. High-efficiency filters are usually not placed on the suction side as high differential pressure can cause pump failure. A fine filter on a pump suction side would require the filter to be very large which will handle the flow and have an extremely low-pressure drop. Fine filters would also tend to load quicker than coarse filters which allow the majority of small particles to pass. Improperly sized suction filters will cause the pump to fail due to cavitation rather than contamination. Many pump OEMs discourage the use of suction filters and suction strainers because of the inherent risk of pump cavitation. Proper return filtration coupled with off-line filtration and proper control of particulate ingression with high-efficiency breathers can often render suction filtration unnecessary.

This filter is located on a suction port of the pump or submerged in the reservoir and attached to the suction line leading to the pump. A suction filter intends to protect the pump from large particles found in the reservoir. This filter is usually a coarse mesh filter or even a magnetic separator. High-efficiency filters are usually not placed on the suction side as high differential pressure can cause pump failure. A fine filter on a pump suction side would require the filter to be very large which will handle the flow and have an extremely low-pressure drop. Fine filters would also tend to load quicker than coarse filters which allow the majority of small particles to pass. Improperly sized suction filters will cause the pump to fail due to cavitation rather than contamination. Many pump OEMs discourage the use of suction filters and suction strainers because of the inherent risk of pump cavitation. Proper return filtration coupled with off-line filtration and proper control of particulate ingression with high-efficiency breathers can often render suction filtration unnecessary.

This filter is generally installed between the pump outlet and the rest of the components in a hydraulic system. The idea here is to protect all components in a given system. This filter must withstand full system pressure and must be capable of handling the max flow of the pump. For systems with a variable workload, the filter must withstand fluctuating flow, pressure cycles, and spikes. In most cases, this is usually the smallest filter but it is also the most expensive.

This filter is generally installed between the pump outlet and the rest of the components in a hydraulic system. The idea here is to protect all components in a given system. This filter must withstand full system pressure and must be capable of handling the max flow of the pump. For systems with a variable workload, the filter must withstand fluctuating flow, pressure cycles, and spikes. In most cases, this is usually the smallest filter but it is also the most expensive.

High-Pressure filters may be installed with or without a bypass valve. The purpose of the integral bypass is to allow a portion of the flow to bypass the filter during cold start conditions or when the filter element is heavily loaded with the contaminant. If a pressure filter with bypass is selected the element must be changed immediately after indication or on a regular preventive maintenance schedule. If the components in the system are very sensitive to contamination (servo valves) a pressure filter with no bypass may be selected to ensure that all of the fluid entering the sensitive components is filtered.

Filters with a bypass utilize elements that are classified as low collapse and can withstand differential pressures up to 450 psid, 30 bar. Filters with no bypass utilize elements that are classified as high collapse and can withstand differential pressures up to 3000 psid or 450 bar. The cost between bypass and non-bypass filter assemblies is minimal, however, high collapse replacement elements can cost up to 300% more than low collapse elements.

Return filters may be installed either in-line or inside the reservoir (In-tank return filter). There are varieties of filters available for each style of assemblies. The designer of the system collects all flow from the system and directs it through the return line filter. Such an arrangement makes certain that the oil in the reservoir will be cleaned to desired ISO specification.

Return filters may be installed either in-line or inside the reservoir (In-tank return filter). There are varieties of filters available for each style of assemblies. The designer of the system collects all flow from the system and directs it through the return line filter. Such an arrangement makes certain that the oil in the reservoir will be cleaned to desired ISO specification.

When a system contains several double-acting cylinders it should be noted that the return flow from the blind end of a cylinder would usually be higher than the maximum flow of the pump. This filter must handle the maximum flow due to flow multiplicationduring cylinder discharge. (For more explanation of this contact Hy-Pro)

Return filters are fitted with internal or external bypass valves as a standard since they are subject to flow rates that may be higher than that of the maximum pump flow rate. The bypass valve protects the housing from bursting and the element from collapse failure.

Over-sizing the return filter is a common practice. This allows the flexibility to enhance the degree of filtration without creating excessively high differential pressure. Normally this is the largest and least expensive filter and a common filter for a mobile hydraulic system.

PILOT LINE PRESSURE FILTER

Some systems have very sensitive components that see only a fraction of the flow. It is very easy to filter the entire system to the required cleanliness level, or as an alternate, a smaller filter with a fine filter media can be installed in the critical leg of a system and the balance of the system can be fitted with an appropriate coarser filter. This might sound like an added expense, but in the long run, it is very economical for a system to have two filters rather than a large single filter with a fine filter media. With one filter the maintenance cost will be greater than the initial cost of installing two filters in a system. In all of the above instances, it should be noted that whenever the filter element requires servicing, the system must be shut down, the element replaced and the system restarted. If such a condition is undesirable, as in power plants, paper mills, etc. then it would be prudent to install a Duplex filter.

Some systems have very sensitive components that see only a fraction of the flow. It is very easy to filter the entire system to the required cleanliness level, or as an alternate, a smaller filter with a fine filter media can be installed in the critical leg of a system and the balance of the system can be fitted with an appropriate coarser filter. This might sound like an added expense, but in the long run, it is very economical for a system to have two filters rather than a large single filter with a fine filter media. With one filter the maintenance cost will be greater than the initial cost of installing two filters in a system. In all of the above instances, it should be noted that whenever the filter element requires servicing, the system must be shut down, the element replaced and the system restarted. If such a condition is undesirable, as in power plants, paper mills, etc. then it would be prudent to install a Duplex filter.

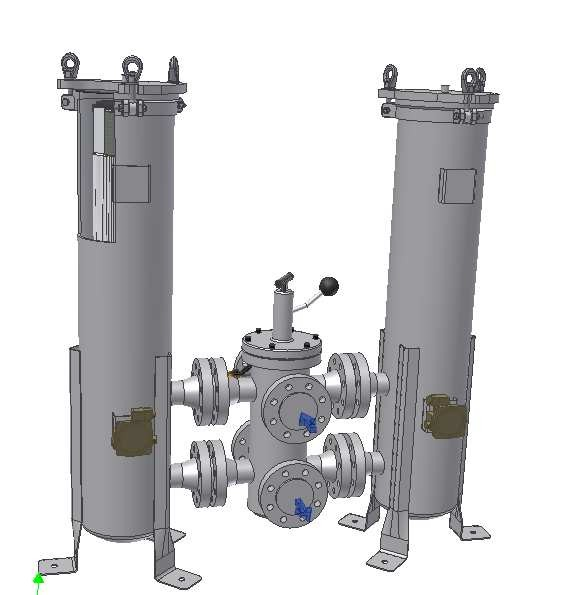

When a single filter assembly is applied, the system must be shut down or bypassed whenever the filter element requires servicing. If such a condition is undesirable (power plant) then it would be prudent to install a Duplex filter.

A duplex features at least two filter housings with a transfer valve separating the housings. The flow can be routed through one housing or both depending on the valve. When one of the filters is fully loaded the operator switches the valve to activate the standby filter and then services the dirty filter. This Duplex filter avoids the shutting down of a system during a filter change.

High flow, low-pressure applications, (lubrication, fuel oil) where shutting down the system to service a filter is not an option, requires the installation of a duplex

The Hy-Pro DLF and DLFM can handle the high flow and high viscosity fluids typically used in lubrication applications. The DLFM may have up to 22 elements per vessel to yield extended element life.

The duplexes feature a true 6-way transfer valve to make switching between filter housings easy.

Some OEMs or the users of a hydraulic or lube system install an off-line filter system. This system is a self-contained filter system. It includes a pump-motor combination as a power source and a range of filtration flexibility to accomplish many desired results. It can easily be connected to a system reservoir. This system can run 24/7 or intermittently.

Some OEMs or the users of a hydraulic or lube system install an off-line filter system. This system is a self-contained filter system. It includes a pump-motor combination as a power source and a range of filtration flexibility to accomplish many desired results. It can easily be connected to a system reservoir. This system can run 24/7 or intermittently.

It can be fitted with a very fine filter element to clean the oil to several ISO codes below the required cleanliness, and can also be used to remove water. Multiple filters can be installed in series to remove water with one element and remove fine particulate with the next or extend element life with a “step down” approach to the degree of filtration. When the filter element reaches its terminal drop, it is serviced without shutting down the main system.

Mobile off-line filtration systems can offer the same impact and flexibility as dedicated off-line filters while performing multiple tasks. They include a pump-motor combination as a power source and filters that can be fitted with many different elements depending on the application.

Commonly referred to as filter carts, they can be fitted with quick disconnect fittings and connected to a reservoir or tote for conditioning, used to filter fluids during transfer, and used for filtering oil during recovery. A

filter cart fitted with two filters in series can have a rapid impact on fluid cleanliness and water content with the appropriate filter elements applied. They can also be fitted with online particle monitors that signal when the desired cleanliness is achieved during flushing applications. If a particle monitor is not specified oil sampling ports should be installed to measure cleanliness.

New oil is typically not suitable for any hydraulic or lubrication system so it is important to avoid contaminating a machine when adding fluids.

High-efficiency breathers are an essential component of proper contamination control. Pleated breathers with glass media can remove particulate down to 1 micron with absolute efficiency.

High-efficiency breathers are an essential component of proper contamination control. Pleated breathers with glass media can remove particulate down to 1 micron with absolute efficiency.

Desiccant breathers control particles, adsorb water from the air, and can even control oil mist exhaust. High-efficiency breathers can extend the life of all filter elements on hydraulic and lubrication systems by controlling airborne ingression, which is one of the major sources of particulate contamination.

Spin-on and Desiccant breather suppliers offer a wide range of adaptors so that any reservoir or gearbox can be retrofitted.

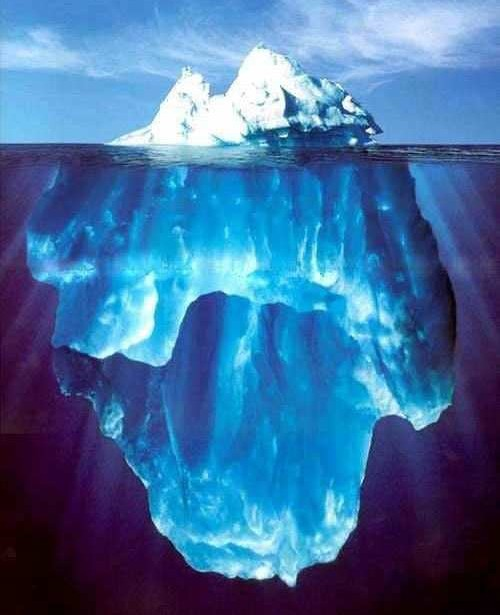

Filters are frequently considered as a necessary evil and are added to a system as an afterthought instead of a valuable asset. Proper filter selection and sizing can provide years of reliable equipment operation and save money that is commonly lost battling contamination-related failures.

Approximately 75 % of all hydraulic component failures are attributed to surface degradation caused by contamination and corrosion. The cost of installing and maintaining suitable filtration is estimated to be 3% of the cost associated with contamination-related issues, the tip of the iceberg.

Hidden costs of runaway contamination include; unplanned downtime, component replacement or repair expenses, fluid replacement, disposal, maintenance labor hours, troubleshooting time and energy, and waste.