Working Principle

Air/oil separators work according to the „principle of coalescence“. Micro-glass fiber layers separate drops of oil from the compressed air and return them in large drops to the oil circuit of the compressor.

The separation process is effective right down to the submicron range.

This ensures that oil consumption in the compressors and oil entrainment into the compressed air networks are kept to a minimum. Oil vapor is not separated.

Air/oil separators can be used with all types of standard compressor lubricating oils, irrespective of whether they are mineral-based, synthetic, or partially synthetic products.

Separation of oil drops

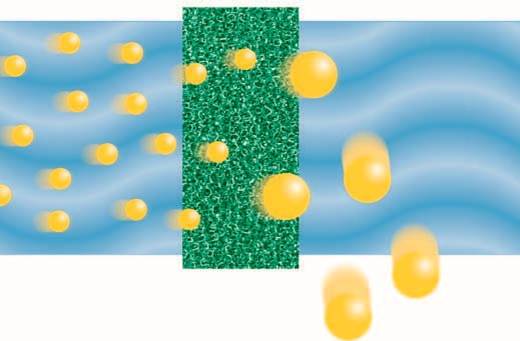

Depending on the size of the drops, various physical separation effects result in the fine drops being adsorbed by the micro-glass fibres.

The number of fibres, fibre diameter and flow velocity have a major impact on separation efficiency. If the design is modified, the interaction between inertia, capillaries, and diffusion effects is optimized.

The fine oil droplets are pressed through the separation medium and as they pass through they come together to form larger drops. Under the effect of gravity, these droplets sink down through the secondary separation medium on the clean side.

The correct choice of material in combination with low flow resistance enables an almost complete separation and redirection of the oil droplets remaining in the airflow. This also applies to load fluctuations around the nominal working point.

Return of separated oil

Depending on the design of compressor, oil is returned in a number of different ways.

In the standard design of air/oil separators, oil flows from the outside to the inside and the drainage oil is drawn off on the dry side through a centrally positioned pipe running from the base cup of the separator.

Design and function

This product family is suitable for flow from the outside to the inside. It can be used for the entire range of current versions of screw-type and sliding vane compressors.

The standard wrap elements are particularly insensitive to design variations and achieve optimal results with regard to separation efficiency and service life.

Pressure resistance

The standard wrap elements designed for pressure differences of at least 5 bar (0.5 MPa).

Separation efficiency

The residual oil content at nominal flow rate and at 7 bar (0.7 MPa) operating pressure is approxi-mately 1 to 3 mg/m3.

Service life

The rise in flow resistance and thus service life primarily depend on the cleanness of the oil and the quality of the air filter. A service life of several thousand hours can be achieved with a well functioning system.

Design and function

This product takes up very little space and is suitable for the entire range of current versions of screw-type and sliding vane compres-sors. In the depth separator ele-ment, oil flows from the outside to the inside.

Pressure drop

The pressure drop at nominal flow rate and at 7 bar (0.7 MPa) operating pressure with a new element is approx. 0.2 bar (20 KPa). If a higher resistance is permitted, the volumetric flow rate can be increased to 1.5 times the nominal flow rate without downgrading performance.

Pressure resistance

Depth separator elements are designed for pressure differences of at least 5 bar (0.5 MPa).

Separation efficiency

The residual oil content at nominal flow rate and at 7 bar (0.7 MPa) operating pressure is approx. 1 to 3 mg/m3.

Service life

The rise in flow resistance and thus service life primarily depend on the cleanness of the oil and the quality of the air filter. A service life of several thousand hours can be achieved with a well-functioning system.

Design and function

This product, using the same concept of the depth separator element take very little space with an additional advantage of as easy servicing.

Has become very common in compressors up to 5.5 m3/min however there are several application where this Separators combined in double or triple are used in bigger compressors.

The pressure drop at a nominal flow rate and at 7 bar (0.7 MPa) operating pressure with a new element is approx. 0.2 bar (20 KPa).

Pressure resistance

Depth separator elements are designed for pressure differences of at least 5 bar (0.5 MPa).

Separation efficiency

The residual oil content at a nominal flow rate and at 7 bar (0.7 MPa) operating pressure is approx. 1 to 3 mg/m3.

Service life

The rise in flow resistance and thus service life primarily depend on the cleanness of the oil and the quality of the air filter. The service life of usually up to 4000 hours can be achieved with a well-functioning system.

For our OEM customers, we can propose the best solution available using the best option available from the market, together with some special solution of other major Suppliers.

For our OES and IAM customers, we can propose a complete range using the best solution available from the market using our 2 decades of experience in the field.